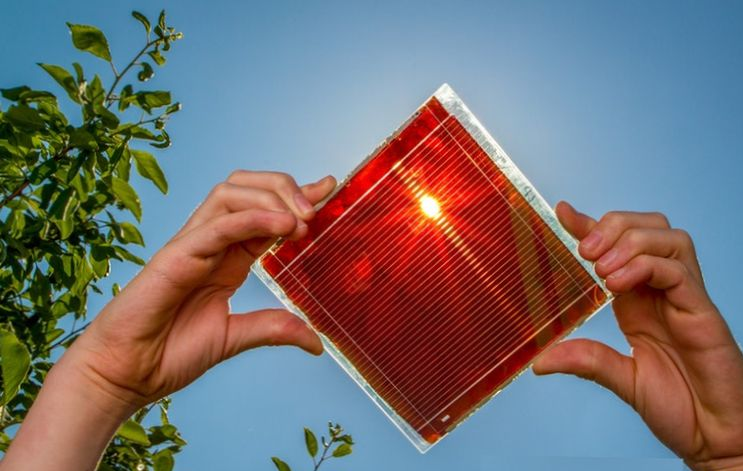

Perovskite solar cells are the most promising type of photovoltaics in the near future. The reason for this is the ubiquity of this mineral in the earth’s crust and a multiple cheaper production technology than that of silicon.

At the moment, perovskite panels have not yet ousted batteries of the first and second generations from the market due to a difficult problem to solve – cell instability to a number of external factors. The main ones are temperature differences and atmospheric moisture, which contribute to the rapid degradation of the perovskite crystal lattice. However, a group of Australian scientists seem to have found the first acceptable solution.

New encapsulating coatings for perovskite

To protect an unstable mineral from external influences, it needs encapsulation – a complete “sealing” into a capsule made of a material with certain properties. For solar panels, such a capsule should be:

- durable,

- as transparent as possible

- very light

- durable,

- heat and moisture resistant.

Only the combination of glass and polymer meets these requirements. But if engineers have no problems with glass, then the search for suitable polymer molecules did not give satisfactory results for a long time.

The first chemists to succeed were the group of Anita WYHo-Baillie from the Australian University of New South Wales. Two fast-curing polymers, polyolefin (PO) and polyisobutylene (PIB), have become candidates for the role of perovskite’s “defenders”.

After university tests, a panel based on a tandem of two types of perovskite with difficult-to-pronounce formulas Cs 0.05 FA 0.8 MA 0.15 Pb(I 0.85 Br 0.15 ) 3 and FA 0.85 MA 0.15 Pb(I 0.85 Br 0.15 ) 3 had to pass the main test – a series of tests, the positive results of which will make it possible to obtain an international quality certificate IEC61215:2016 .

The requirements include:

- uninterrupted operation at a temperature of 85 ° C for 1000 hours;

- 10 cooling cycles down to -40°C followed by heating up to the previous values of +85°C (imitation of extreme day/night temperature fluctuations);

- maintaining the physical and technical parameters of the cells at a level of more than 90% after the completion of the test.

Panels encapsulated with polyolefin (PO) did not pass the test – the best of the samples withstood a series of heating / cooling for only 564 hours. On the other hand, batteries encapsulated in polyisobutylene (PIB) with a surface protective coating of very thin glass lasted 1800 hours and went through 75 heating / cooling cycles ! At the same time, showing an incredible efficiency for perovskite cells of 25.2% , with the previous record of only 3.8%.

Expected practical results

There is no doubt that the data obtained will play a huge role in accelerating the process of mass production of simple and cheap solar cells based on perovskites. Although some auxiliary tasks still remain unresolved.

In addition to thermal and moisture stability, physicists need to find a way to reduce current losses at the junction of two materials – generating and converting radiation. So far, specialists from Germany have achieved the best results here, due to the use of an intermediate layer of oxidized tungsten.

In addition, it is necessary to increase the life of the cells without noticeable degradation of the working layer. But no one doubts the imminent conquest of the “solar” market by perovskite.